3D Printed Heat-Exchangers for Coffee-Machines (3D COFFEE)

3D Coffee wants to create an innovative heat exchanger for more sustainable, and high-quality coffee preparation.

3D Coffee wants to create an innovative heat exchanger for more sustainable, and high-quality coffee preparation.

Today, espresso machines are either electro-thermic or traditional (e.g., moka pots). The former, which allows for a good coffee delivery thanks to electronic process control, is quite expensive, noisy, and has a higher environmental impact. The latter, on the contrary, being compact, more environmentally friendly, and cheaper, gives a lower coffee quality as it cannot control temperature and pressure during the preparation process. In this scenario, the 3D coffee project aims to develop a passive heat exchanger for coffee machines (electric and non-electric) with thermodynamic characteristics such as to guarantee the preparation of coffee in a more sustainable, performing, economical and quality way. Funded by the European project DIH-World , 3D coffee is a six-month experiment led by Additive Appliances in team with Kilometro Rosso. Additive Appliances is a startup with a strong experience in 3D printing applications for the customization of numerous low environmental impact appliances.

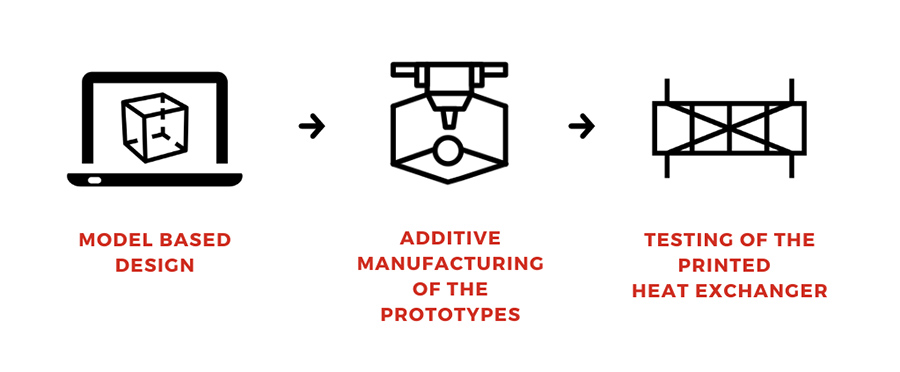

Model-Based Design to find the optimal topology of a conformal, highly-efficient and passive heat-exchanger

Validation of the heat-exchanger model against a set of 3D printed prototypes and their realization

Test of the performance of the heat-exchanger in enabling a more efficient and sustainable coffee preparation

Duration 6 months

Kick-off meeting 01/10/2021

Mid-Term Report 24/01/2022

Final Event 06/04/2022

End of the Experiment

14/04/2022

DIH-World Community Day

29/04/2022

Kilometro Rosso’s role is to 3D print Additive Appliances’ prototype from aluminium powders and to optimize the printing process via a Direct Metal Laser Sintering printer equipped with in-process quality monitoring. This work will be conducted with the support of Lisa Tech, the Living Space for Additive Technologies through its prime Metal AM infrastructure and expertise. In addition, Kilometro Rosso is in charge of communicating and disseminating the project content and results.